Sintering silicon carbide (SiC) using Spark Plasma Sintering (SPS), also known as Field-Assisted Sintering Technique (FAST), is a rapid and efficient process that leverages electric current and pressure to achieve high-density ceramics at lower temperatures and shorter times compared to conventional methods like vacuum sintering. Below is a detailed explanation of each step involved in SiC sintering via SPS:

Description: The process starts with high-purity silicon carbide (SiC) powder, typically in the submicron or nanoscale range.

Details:

Alpha-SiC or beta-SiC powder is selected based on the desired properties.

Additives such as boron carbide (B₄C), carbon (e.g., graphite), or aluminum oxide (Al₂O₃) may be mixed with the powder to promote densification and reduce sintering temperature.

The powder is often milled (e.g., ball milling) to ensure uniform particle size and distribution, improving packing efficiency.

Purpose: Prepares a homogeneous starting material for effective sintering.

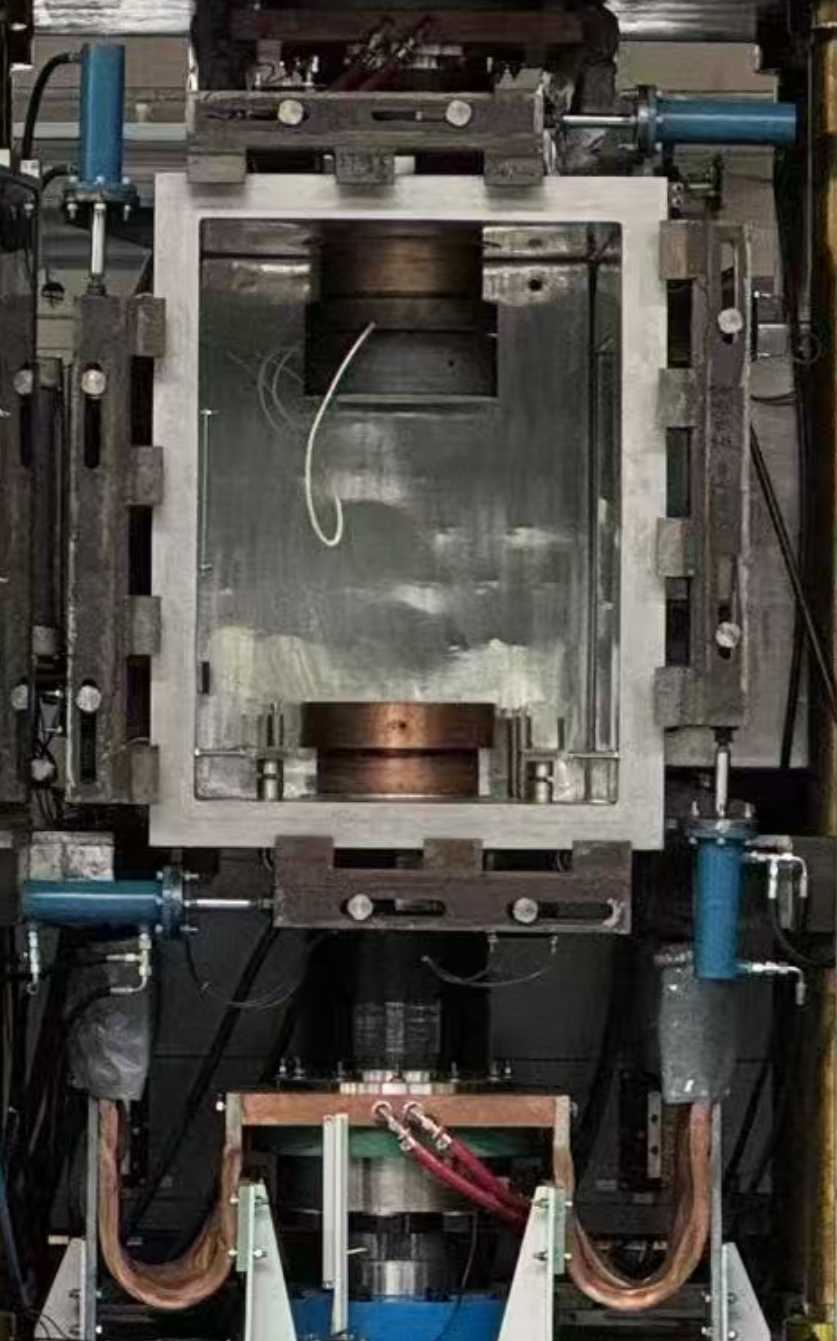

Description: The prepared SiC powder is loaded into a conductive die, typically made of graphite, designed for SPS.

Details:

The powder is poured into the cylindrical die and lightly compacted to form a green body. No additional binders are typically required, unlike in conventional sintering.

The die is sandwiched between two graphite punches, which will apply pressure and conduct current during sintering.

The assembly is placed inside the SPS chamber, which is then sealed.

Purpose: Sets up the material for simultaneous application of pressure and electric current.

Description: The SPS chamber is evacuated to create a low-pressure or vacuum environment.

Details:

A vacuum (e.g., 10⁻² to 10⁻³ Pa) or inert gas (e.g., argon) atmosphere is established to prevent oxidation of the SiC or graphite die at high temperatures.

This step is critical to avoid unwanted reactions with oxygen or nitrogen.

Purpose: Ensures a clean sintering environment for optimal material properties.

Description: The SPS system applies a pulsed direct current (DC) through the graphite die and powder compact while simultaneously applying uniaxial pressure.

Details:

Temperature ramps up rapidly (e.g., 50–200°C/min) to an intermediate range (e.g., 1000–1500°C).

The pulsed current generates localized plasma or spark discharges between particles, cleaning surface oxides (e.g., SiO₂) and enhancing particle bonding.

Pressure is typically set between 20–100 MPa, depending on the material and die strength.

Purpose: Prepares the powder for densification by removing impurities and initiating neck formation between particles.

Description: The temperature is increased to the sintering range, and densification occurs under combined current and pressure.

Details:

Peak temperature typically ranges from 1700–2000°C for SiC, lower than conventional sintering (1900–2200°C), due to the enhanced kinetics from the electric field and pressure.

The pulsed DC (e.g., 1000–5000 A, depending on the system) flows through the conductive die and, to some extent, the SiC powder (if sufficiently conductive with additives), causing rapid heating and localized Joule heating at particle contacts.

Sintering time is short, often 5–20 minutes, compared to hours in vacuum furnaces.

Densification mechanisms include plastic deformation, diffusion, and grain boundary sliding, accelerated by the electric field and pressure.

Purpose: Achieves near-theoretical density (>98%) with minimal grain growth, preserving fine microstructure.

Description: After holding at the sintering temperature, the current is turned off, and the sample is cooled under controlled conditions.

Details:

Cooling rates are typically fast (e.g., 50–100°C/min) but can be adjusted to avoid thermal shock.

Pressure may be maintained or gradually released during cooling to prevent cracking.

The vacuum or inert atmosphere is sustained until the temperature drops below 1000°C.

Purpose: Solidifies the dense SiC structure while minimizing residual stresses.

Description: The sintered SiC compact is removed from the die and inspected.

Details:

The graphite die is disassembled, and the sintered part is extracted. Surface layers may require grinding or polishing if carbon from the die has diffused into the SiC.

Characterization (e.g., density measurement, SEM, XRD) confirms the material’s properties, such as hardness, thermal conductivity, and microstructure.

Purpose: Verifies the quality of the sintered SiC and prepares it for its intended application.

Speed: SPS reduces sintering time significantly (minutes vs. hours) due to rapid heating and enhanced mass transport.

Lower Temperature: The electric field and pressure allow densification at 200–300°C below conventional methods.

Microstructure Control: Short sintering times limit grain growth, resulting in finer, stronger SiC ceramics.

Equipment: SPS systems typically feature a water-cooled chamber, high-current power supply, and hydraulic press, all precisely controlled.