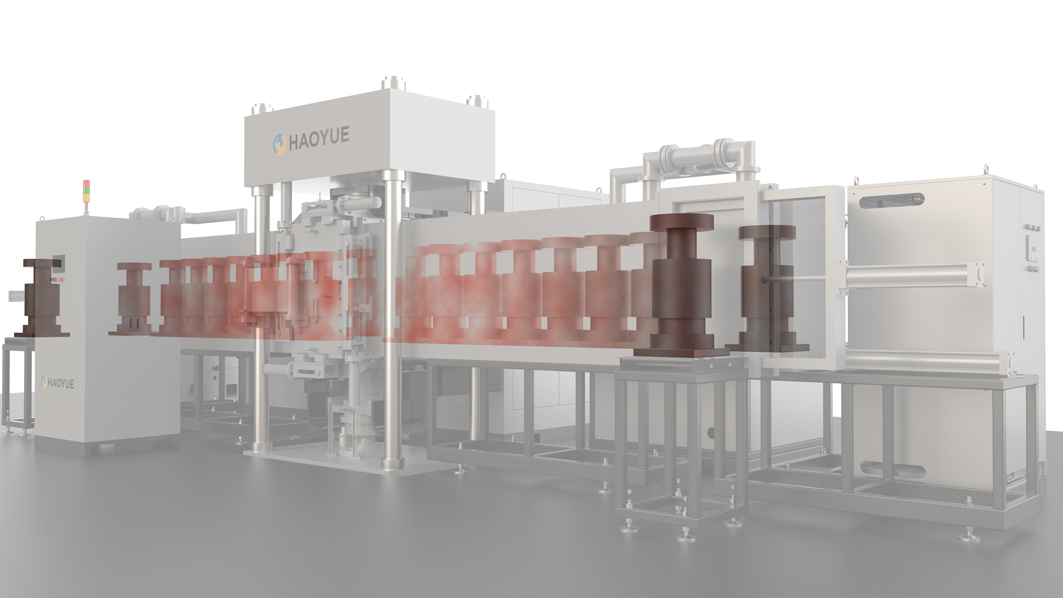

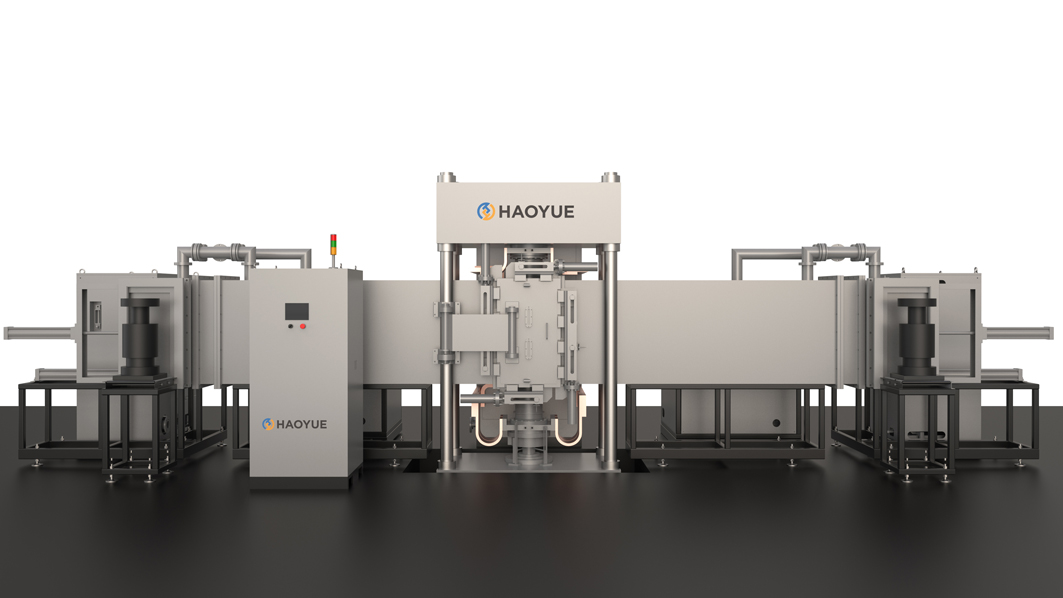

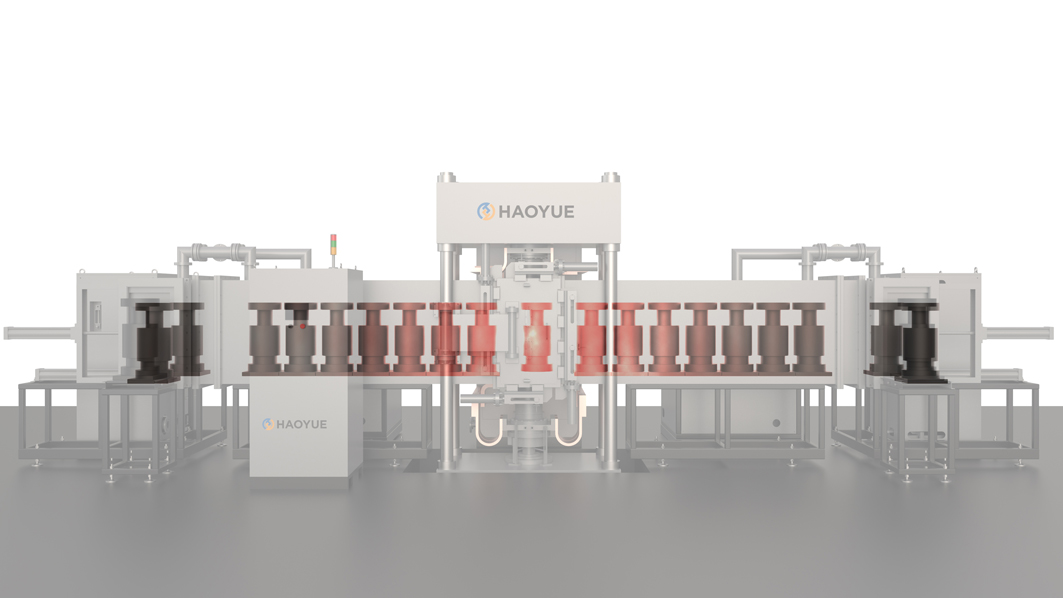

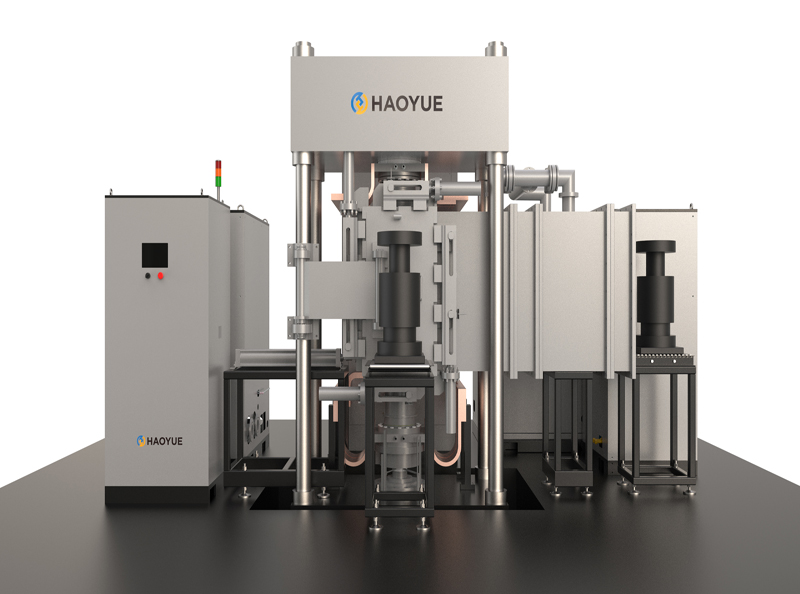

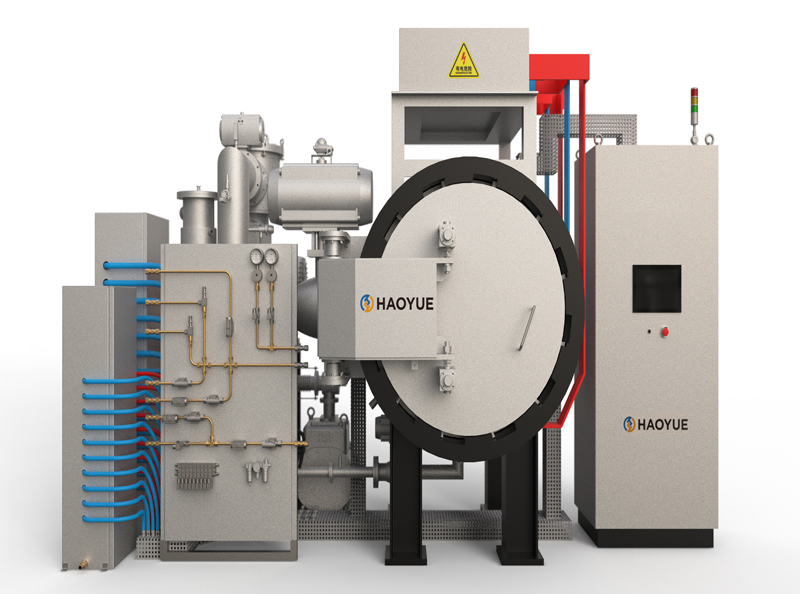

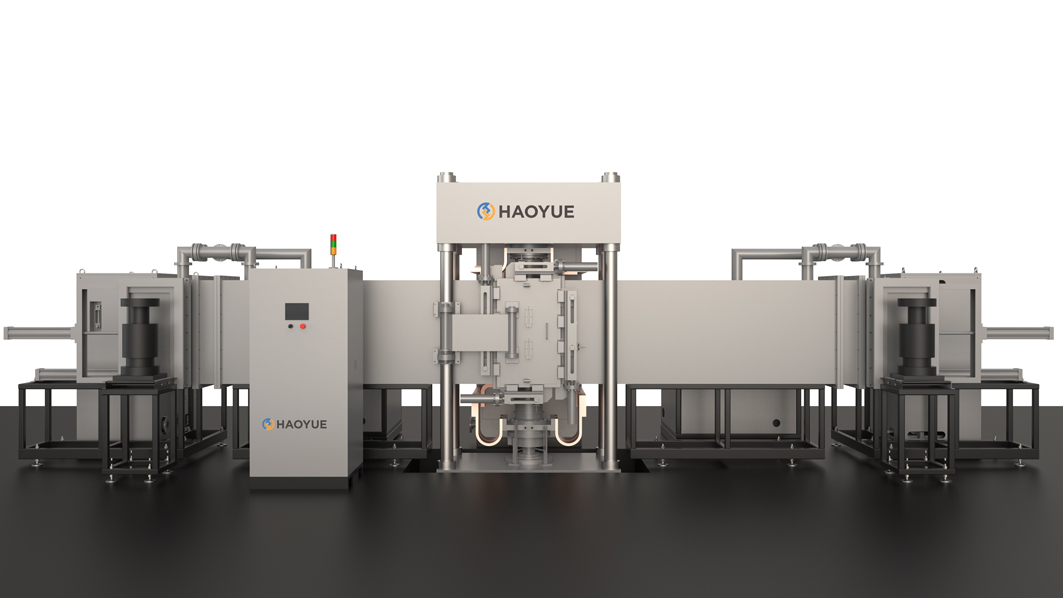

S series Continuous SPS Spark Plasma Sintering System

High Production Efficiency / High Automation Program / Good Temperature Uniformity / Fast Heating Speed / High Pressure Accuracy / Good Safety Performance

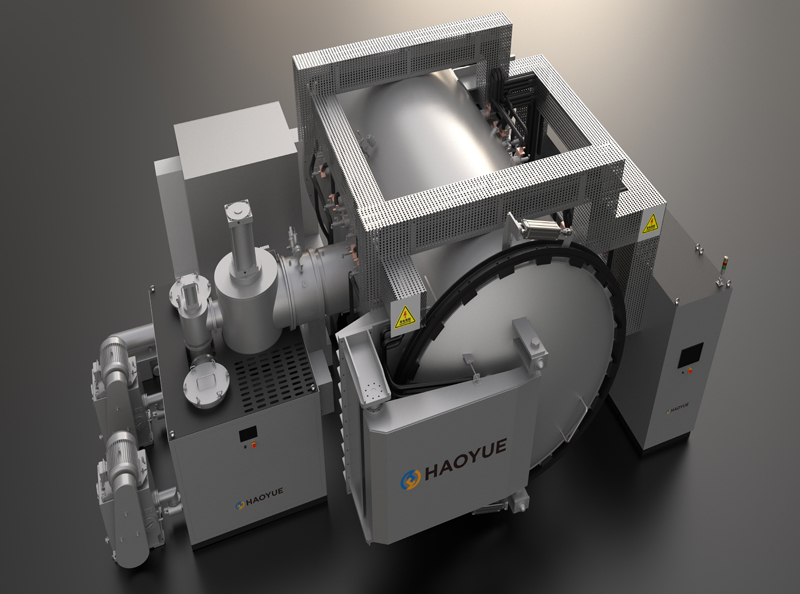

The SPS (Spark Plasma Sintering) discharge plasma sintering system is one of the most advanced sintering systems in the world today. It is a new rapid sintering technology that applies pulse current and axial pressure between two electrodes for powder sintering densification. It has distinct characteristics such as fast heating rate, short sintering time, controllable microstructure, energy conservation and environmental protection. It can be used to prepare metal materials, ceramic materials, composite materials, as well as nano bulk materials, amorphous bulk materials, gradient materials, etc..

Technical Data

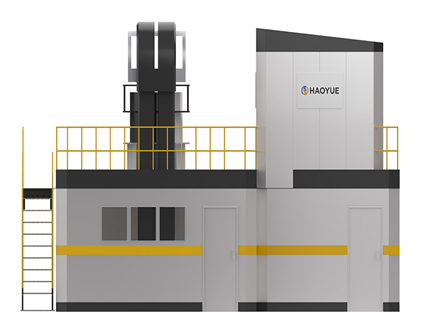

Haoyue Continuous SPS Spark Plasma Sintering System delivers cutting-edge sintering performance with high energy efficiency, fast heating rates, and excellent microstructural control. Designed for continuous, automated production, this SPS system offers unmatched scalability and precision for both R&D and industrial applications.

Due to the discharge effect caused by the application of DC pulse current during the SPS process, there are several unique characteristics:

By adopting a multi station design, continuous production can be achieved, resulting in a doubling of effciency.

It can quickly heat up and cool down, signiÿcantly shorten production time, and reduce production costs (with a heating rate of up to 200°C/min);

Compared to traditional sintering processes, materials with more uniform, denser, and smaller grain sizes can be obtained in a shorter time;

No need for powder preforming, it can be directly sintered into a dense body;

We adopt our professional DC pulse power supply technology, which has fast sintering speed, stability and reliability, and good energy-saving effect;

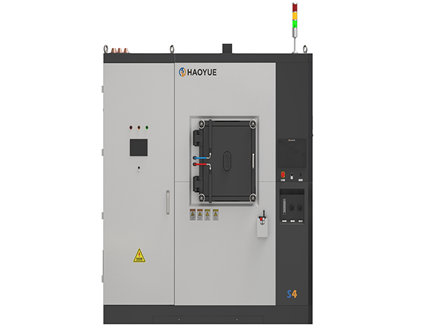

High pressure accuracy: Adopting a servo pressure control system, the pressure accuracy is ±3‰;

High degree of automation: If an automatic loading and unloading system is selected, all processes can be fully automated, digitized, intelligent, and without the need for manual intervention;

Good safety performance: Adopting HMI+PLC+PID pressure sensing control, safe and reliable; Good sealing performance: The dynamic pressure heads are sealed with corrugated pipes to ensure no air leakage.

Specifications

| No. | Device Form | Sample Dia. (mm) | Pressure (kN) | Ultimate Vaccum (Pa) | Max. Heating Power (kW) | Current (A) | Voltage (V) | Operating Temperature (°C) |

| S-150C | Continuous | 150 | 1000 | 1 | 300 | 30000 | 10 | 2200 |

| S-200C | Continuous | 200 | 2000 | 1 | 400 | 40000 | 10 | 2200 |

Key Features:

Continuous Operation: Automated feeding and unloading ensure uninterrupted sintering, perfect for large-scale production.

Rapid Heating & Cooling: Achieve heating rates up to 1000°C/min with fast response thermal control.

Precise Pressure & Temperature Control: Uniform densification with programmable load profiles.

Low Energy Consumption: Efficient power use with advanced graphite tooling and vacuum/inert gas chambers.

Modular Design: Adaptable for various mold sizes, powder types, and materials.

Application

Sintered nanomaterial without significant grain growth

FGM (Functionally Graded Materials); Composite materials; Innovative carbide metals; Aluminum and copper alloys as well as intermetallic compounds

Structural and functional ceramics; Electronic Materials; Sputtering target material; Bioma materials; Porous materials; Magnetic materials

Typical Applications:

Sintering of functional ceramics and thermoelectrics

Hard metals and advanced composite materials

Fuel cell and battery electrode manufacturing

Aerospace components and biomaterials

Nano-powder densification with minimal grain growth

Get a Customized Continuous SPS Solution Today

Whether you’re scaling up production or pushing material boundaries in your lab, Haoyue’s Continuous SPS Spark Plasma Sintering Machine is engineered for precision, reliability, and efficiency. We support full customization based on material, size, and throughput requirements. Contact our engineering team for technical consultation and quotations.