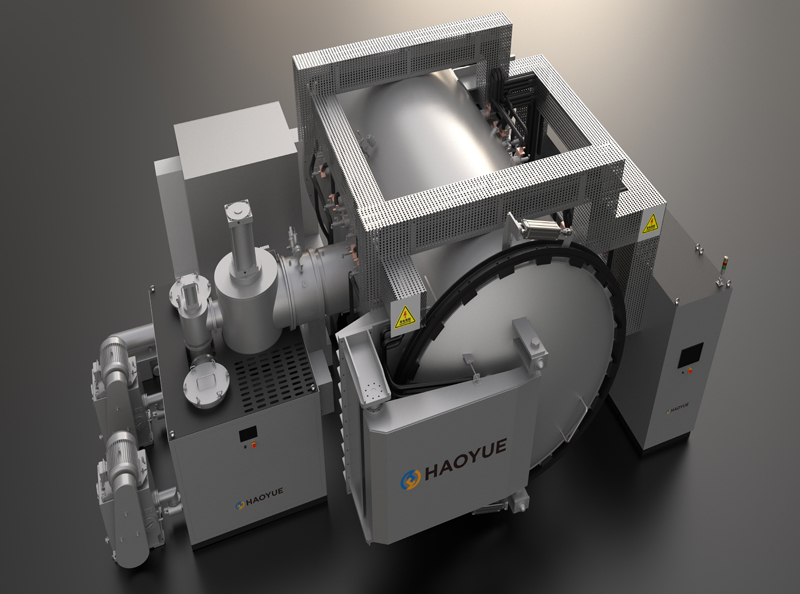

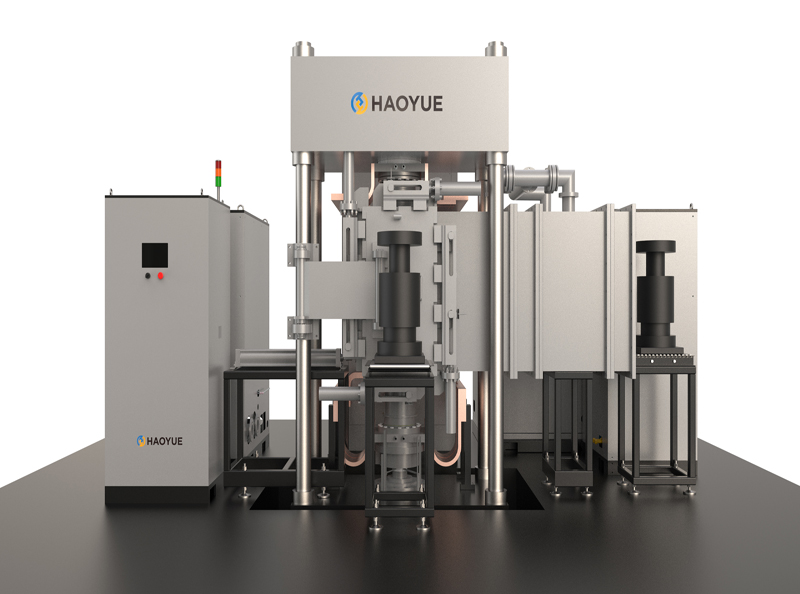

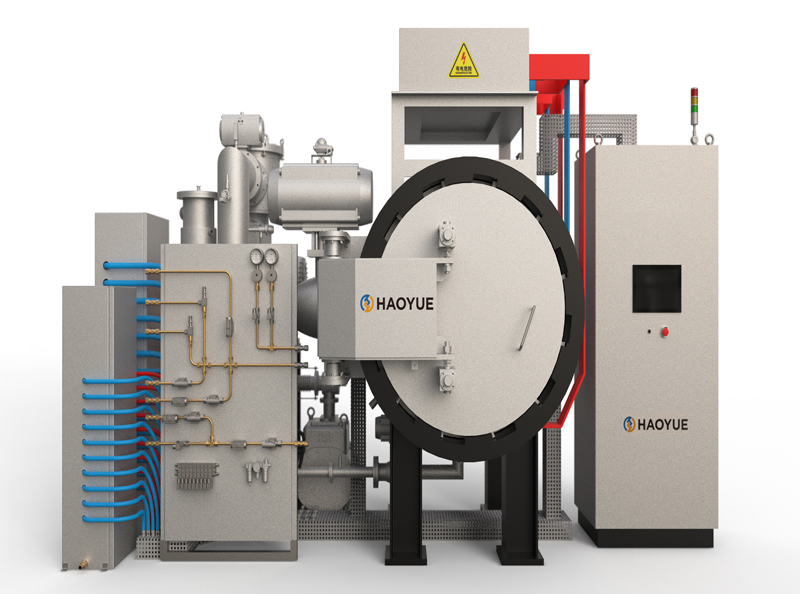

V series Vacuum Furnace (Induction)

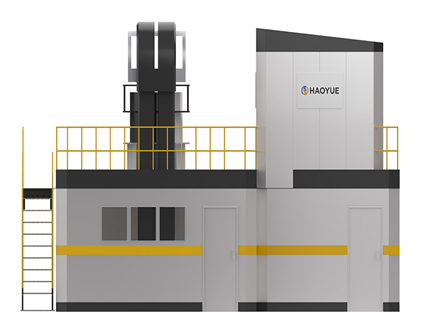

Vacuum induction furnace adopts induction heating method and is mainly used in ceramics, hard alloys, and composite materials, Composite materials can be sintered and annealed at high temperatures in vacuum or protective atmosphere, and can also be used for high-temperature heat treatment of metal materials under high vacuum conditions or degassing treatment of precious metal materials. The structural design of this equipment is advanced and reasonable, and the design and manufacturing comply with corresponding national and industry standards and specifications, which can meet the user's usage requirements.

Its supporting products and components have international advanced level and can adapt to long-term, stable, safe, and reliable production needs.

The energy-saving effect of the equipment is good. Convenient and simple to use, operate, and maintain, with beautiful appearance, safe and reliable, and excellent after-sales service

Technical Data

Vacuum Induction Melting Furnaces – Industrial Vacuum Induction Furnace by HaoYue

Industrial Vacuum Induction Furnace by HaoYue delivers rapid, uniform heating in vacuum or protective atmospheres for sintering, annealing, and heat treatment of ceramics, hard alloys, composites, and metals. Combining a horizontal side-opening design with advanced HMI + PLC + PID control, it achieves up to 40 °C/min below 1600 °C and 20 °C/min above 1600 °C, optimizing throughput and energy efficiency . As part of HaoYue's Vacuum Induction Melting Furnaces lineup, this Industrial Vacuum Induction Furnace supports sintering, degassing, and high-vacuum metallurgical processes with an ultimate vacuum of 5 Pa . Users benefit from modular components, multi-zone temperature control (±5 °C), and expandable gas-atmosphere capabilities for tailored applications .

HaoYue's Industrial Vacuum Induction Furnace features a horizontal side-opening structure for precise loading and unloading, ensuring operator safety and process reproducibility. Utilizing induction heating coils that generate high-frequency electromagnetic fields, it offers contact-less, efficient heating tailored to vacuum environments . Thermal simulation-optimized insulation modules minimize heat loss, extending component life and reducing energy consumption.

Key Features

| Feature | Description |

| Rapid Heating | Achieves up to 40 °C/min below 1600 °C and 20 °C/min above 1600 °C, accelerating cycle times and throughput. |

| Multi-Zone Temperature Control | Multiple thermocouples ensure ±5 °C uniformity across the chamber for consistent material properties. |

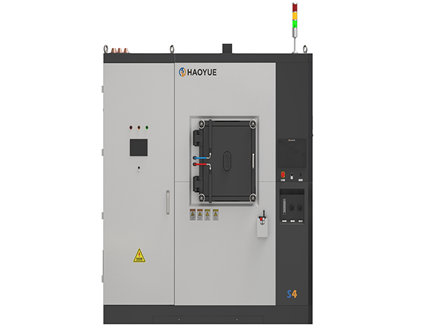

| Advanced Control System | Integrated HMI + PLC + PID enables automated, precise temperature and vacuum control with safety interlocks. |

| High Vacuum Performance | Ultimate vacuum down to 5 Pa supports degassing of precious metals and prevents oxidation during heat treatment. |

| Expandable Gas Atmospheres | Enables sintering, annealing, or hydrogen treatments in custom gas environments for advanced material synthesis. |

| Modular Components | Replaceable heating elements and insulation layers minimize downtime and reduce maintenance costs. |

Adopting a horizontal and side opening door structure: high loading and unloading accuracy, easy operation;

Fast heating: heating rate of 40°C/min (˛1600°C), heating rate of 20°C/min

(>1600°C);

Adopting multi temperature zone control: reserving multiple temperature measurement holes for high-temperature monitoring purposes;

Good safety performance: Adopting HMI+PLC+PID pressure sensing control, safe and reliable;

Good design optimization: The induction thermal ÿeld in the heating chamber has been simulated and calculated in thermal state, with very high temperature uniformity and compatibility, The heating elements and insulation layer are designed with modular optimization;

Expandable: capable of sintering, annealing, hydrogen gas, etc..

Precautions & Maintenance

Vacuum Integrity: Inspect seals, valves, and pump oil levels daily to prevent leaks and maintain performance .

Temperature Limits: Do not exceed 2400 °C to avoid damage to heating elements and insulation.

Atmosphere Purity: Use specified gases (argon, hydrogen) to prevent contamination and ensure consistent results .

Loading Capacity: Adhere to model guidelines (e.g., V6CO24: 600 × 600 × 900 mm) to avoid overloading.

Routine Maintenance:

Daily: Check electrical connections, cooling water flow, and chamber cleanliness.

Monthly: Clean insulation surfaces and verify thermocouple calibration .

Annual: Replace graphite coils or insulation modules and calibrate vacuum gauges.

As part of HaoYue's Vacuum Induction Melting Furnaces series, this Industrial Vacuum Induction Furnace sets the standard for precision, efficiency, and safety in vacuum heat treatment and induction vacuum heat treatment furnaces, backed by global after-sales support.

Specifications

| No. | Model | Chamber Size (mm) | Ultimate Vacuum (Pa) | Operating Temperature(℃) | Applications |

| V6CO24 | VHSco-60/60/90-2400 | W600*H600*D900 | 5 | 2000/2400 | Sintering /Annealing |

| V8CO24 | VHSco-80/80/120-2400 | W800*H800*D1200 | 5 | 2000/2400 | Sintering /Annealing |

Application

This electric furnace is a periodic operation type, which can be used for graphite electrodes, ceramics, etc. under high temperature and high vacuum conditions, Sintering treatment can also be carried out under the condition of filling a protective atmosphere, which is widely used in many steel and metallurgical industries, The ceramic industry and other industrial industries have been widely applied, such as hard alloys, ceramics, refractory materials, and powder metallurgy gold, ultra-high temperature material ÿring, and other applications are required.

Ceramics & Refractories: High-temperature sintering of advanced ceramics in controlled atmospheres.

Metallurgy: Annealing, degassing, and heat treating of metals such as titanium and superalloys .

Powder Metallurgy: Sintering of hard alloys and composite powders for aerospace and tooling applications.

Semiconductors: Ultra-clean vacuum processing for semiconductor wafers and materials .

Precious Metals: Vacuum degassing and melting for gold, silver, and platinum components using Vacuum Induction Melting Furnaces technology .

Research & Aerospace: Development and testing of ultra-high-temperature materials for R&D centers and aerospace industries .

Main Ingredients

Induction Heating Coils: Provide rapid, uniform heating without direct contact, reducing contamination risk .

Vacuum System: Rotary vane and diffusion pumps achieve and maintain high vacuum for degassing and melt refining .

Thermal Insulation Modules: Multi-layer refractory insulation minimizes heat loss and stabilizes process temperatures .

HMI + PLC Control Panel: Centralized interface for real-time monitoring and automation of temperature, vacuum, and safety interlocks .

Water-Cooling System: Protects critical components during prolonged high-temperature cycles.

Safety Interlocks: Pressure and temperature sensors trigger emergency shutdowns to safeguard personnel and equipment.